Prior to the development of adhesive tape, glues and epoxies were used to secure or seal surfaces. They were messy and inconvenient, and they dried to a permanent hard finish that was difficult to remove. Glues and epoxies form a bond using a chemical reaction that is not applicable to small, everyday jobs.

Adhesive tapes use a tacky resin such as silicone, acrylics, or rubbers to create their stickiness and rely on physical action such as pressure to make their bonds. The solid adhesive in tape has a low energy surface where its molecules are in constant motion or energized, creating looser bonds, which allows the molecules to flow easily in solid form into the pores of the substrate. With a little pressure, the molecules flow into the substrate and form a solid physical bond.

The Science of Adhesion

The concept of adhesion is based on the idea that various substances can hold surfaces together by some form of attachment in which one set of molecules sticks to another type of molecule. In addition, the process uses the concept of cohesion, where molecules stick to themselves. Adhesive tape uses both adhesion and cohesion, where adhesive molecules adhere or stick to a substrate but also themselves. These two factors are necessary for adhesive tape to maintain its hold on a surface.

Parts of the Bond

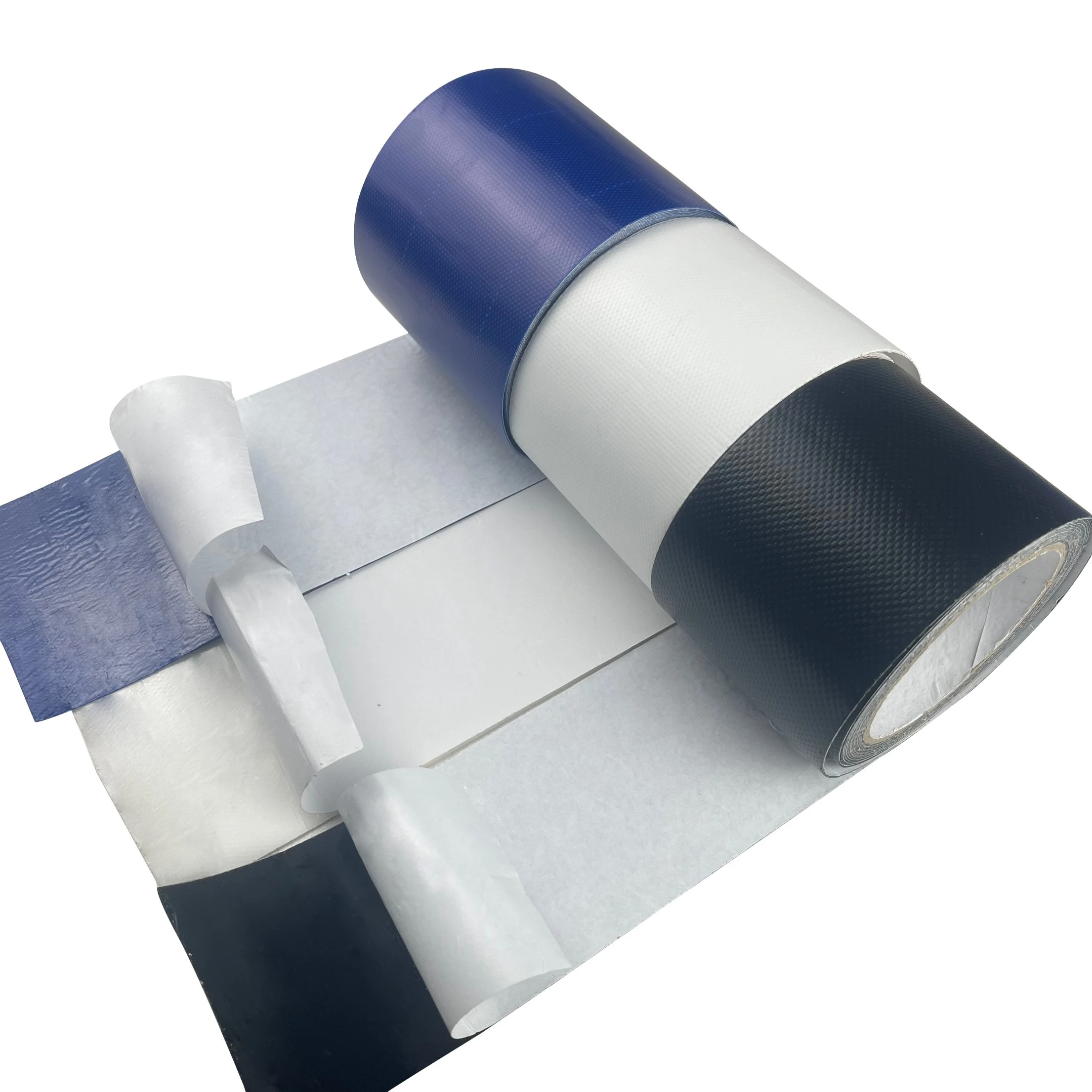

The bonding layer made by an adhesive tape, shown macroscopically in the image below, presents a cross-section of a bond. The layer consists of an adhesion zone, cohesion zone, and a transition layer.

Various mechanisms make it possible for two surfaces to adhere to each other. The process of adhesion involves four basic concepts that enable tape to bond to a substrate surface.

- Chemical Adhesion – Chemical adhesion is defined by molecular contact between the substrate and the adhesive, with bonds forming between molecules of the adhesive and the substrate surface. It is the strongest of the adhesive mechanisms.

- Mechanical Interlocking Adhesion – Mechanical interlocking adhesion happens when the adhesive flows into the pores of the substrate, which increases the contact between the adhesive and substrate. The flow continues with bonding tape, slowly causing it to build strength.

- Diffusion Adhesion – In diffusion adhesion, the adhesive penetrates and becomes entangled with the polymeric substrate, which creates an interface with the entangled polymer chains to bond the substrate and the adhesive.

- Electrostatic Adhesion – Electrostatic adhesion refers to the attraction between two oppositely charged surfaces that draws them to each other.

Mechanism of Action

The foundation of the mechanism of adhesion is based on absorption theory, or the concept that substances stick together because of the contact between molecules. The four adhesion mechanisms substantiate and support the premise of absorption theory.

For adhesives to work, they must be spread over the surface of the substrate. In the sticking process, the adhesive surface of the tape sticks to the surface molecules of the substrate like millions of minuscule magnets. Stronger bonds are formed where the adhesive and the substrate merge to form a strong chemical bond. The combination of the adhesive and the substrate form a new chemical, a process referred to as chemisorption.

- Adhesion: Adhesion is the ability of an adhesive substance to adhere to another surface using one of the four mechanisms of attraction between the materials. When adhesive molecules come in contact with the substrate, adhesion occurs at the microscopic level through intermolecular forces. This is based on van der Waals forces regarding weak intermolecular forces.The concept of van der Waal forces is dependent on distance. When molecules are close, their forces are attractive. If the distance is 0.6 nanometers, the force is weak and cannot be seen. When the distance is less than 0.6 nanometers, attraction occurs, a foundational adhesion principle.Surface energy determines the wettability of the substrate when it makes contact with the adhesive. The wettability of the adhesive allows it to penetrate the surface of the substrate to form a bond using one of the four adhesive mechanisms.Surface energy is the sum of the intermolecular forces regarding their attraction and repulsion energies and how a liquid exerts force on the surface of a solid. Where the substrate has high surface energy, an adhesive easily flows over it and covers more area. Examples of high-energy substrates are polycarbonate, polyvinyl chloride, and zinc.If the substrate has low surface energy, the adhesive builds up as “small beads” covering a minute area. Types of low surface energy substrates include polytetrafluoroethylene (PTFE), rubber, and powder coatings.

Surface contaminants reduce surface energy and prevent the fusion of an adhesive to the substrate. Types of surface contaminants include dust, fingerprints, oil, grease, moisture, and various forms of residue, such as coatings. For the adhesion process to be successful, pretreatment of the surface is necessary, which removes surface contaminants, enhances surface energy, and improves adhesive bonding. - Cohesion: Cohesive force is the bonding of the molecular chains of the tape that are expressed as shear resistance or retention force that occurs after bonding. When tape has good cohesion, it is resistant to high temperatures, with low viscosity and exceptionally strong retention.Cohesive forces attract the molecules of a liquid by pulling them inward. Surface molecules of the liquid have attractive forces that bind them together, a phenomenon responsible for the property of a liquid referred to as surface tension.In adhesion, surface tension is the ability of the adhesive to resist deformation on the surface of a solid, reducing its surface area. In the case of adhesive tapes, the molecules of the adhesive have to have strong, cohesive forces to hold and maintain the bond.Silicone adhesive tape has good adhesion with low surface energy, but it is heat and weather-resistant with good electrical insulation properties and chemical resistance.Adhesion and cohesion are the properties that engineers consider when designing tape. The two forces work together to form strong, consistent bonds for a high surface energy substrate for low surface tension adhesives. To have good wetting, adhesive forces must be greater than cohesive forces and contact at less than a 90° angle.

- Tackiness: The tackiness factor refers to how a pressure-sensitive tape sticks to the substrate when minimal pressure is applied. The adhesive is activated by 14.5 psi to 29 psi pressure. The amount of pressure time varies per the type of adhesive, the nature of the substrate, and the substrate surface’s consistency. When an adhesive tape is high in tackiness, less time and pressure are required to ensure a proper bond.Viscoelastic materials are viscous and elastic. They behave like fluids and elastic solids and have particles that temporarily connect. Their flexibility allows them to slide along each other like fluids. When low pressure is applied to tape, its viscosity decreases, causing the adhesive to flow onto the substrate at a microscopic level. Its elastic properties help it regain its viscosity to form a strong intermolecular force with the substrate.Rolling Ball and Loop Tack Tests are used as quality control checks to assess the tackiness of adhesive tapes.

- Rolling Ball Test: The rolling ball test directly gauges the adhesive behavior of the adhesive tape. A steel ball with a standard weight and diameter is rolled from the top of an inclined track consisting of the sticky side of the tape. The tackiness is measured by the distance traveled by the ball on the sticky tape track; the shorter the distance, the greater the tack.

- Loop Tack Test: The loop tack test is a quantitative and repeatable method to assess adhesive tape tackiness. A loop of adhesive tape is attached to the probe of a tensile tester machine. The loop is made to contact with a horizontal surface for a short time before a tool pulls it away. Numerical values of the bond‘s tensile strength are recorded and subjected to evaluation.

- Rolling Ball Test: The rolling ball test directly gauges the adhesive behavior of the adhesive tape. A steel ball with a standard weight and diameter is rolled from the top of an inclined track consisting of the sticky side of the tape. The tackiness is measured by the distance traveled by the ball on the sticky tape track; the shorter the distance, the greater the tack.

- Surface Energy: Surface energy is the attraction or repulsion between a substrate and another material. When a surface has high surface energy (HSE), molecules easily flow over the surface. With low surface energy (LSE), liquids bead up instead of flow. In the case of adhesives, surface energy influences how an adhesive is capable of wetting out the substrate.Surfaces with LSE are difficult to bond because the surface resists the adhesive’s wetting out, creating low surface contact and adhesion. With HSE, the adhesive wets out easily, with increased surface contact forming a strong bond.For adhesive tape to bond with an LSE substrate, the surface must be modified by changing its chemical composition to increase its surface energy. Techniques such as flames, plasma treatments, acid etching, and solvents may be used. In addition, there are specially formulated adhesives capable of bonding with LSE substrates that contain modified acrylics and synthetic adhesives. Rubber adhesives are often used since they are soft and flow well.