Introduction

This article takes an in depth look at PTFE Tape.

In this article you will learn more about topics such as:

- What is PTFE Tape

- Tape Manufacturing Process

- Types of PTFE Tapes

- Application of PTFE Tape

- And Much More…

Chapter 1: What is PTFE Tape?

PTFE stands for polytetrafluoroethylene and is a synthetic fluoropolymer used widely in many industries and many other applications. PTFE is also commonly referred to as thread seal tape, teflon tape, and plumber’s tape. PTFE tape is a simple and highly adaptable lubricating material used as a sealant in plumbing for pipes and ductwork. This lubricating property of these tapes helps for the deep and prolonged setting of the thread and also helps in preventing thread seizures after being unscrewed. It is a professional adhesive tape, so it comes in specific cuts rolled on the spools. Each spool is of specific width and is pre-cut to a specific range. Thread seal tape is covered in a plastic case to protect its adhesive material from any damage during storage.

This PTFE tape is a long synthetic polymer that is used as a lubricating material and deformable filler that helps to seal the joint without hardening it. Rather this lubrication property makes it easier to tighten. It helps the thread’s both pieces come in contact with each other and protects it from physical wear and tears. It also helps the seal lock and prevents connection leakage. The key property of this tape is that it is hydrophobic and has extremely low friction. These properties make it an excellent choice in the piping and plumbing industries. Usually, the PTFE tape is wrapped around the male thread in the direction of tightening about three times before it’s screwed in place. The chemical inertness of PTFE tapes helps in preventing cross linkages with other polymers. This makes it a good choice for applications where there is water, chemicals, or other solvents present. These tapes can also be made of polyethylene (PE), a low cost plastic that also shows resistance to chemicals and other solvents.

This thread tape has certain specifications such as:

- Density

- Tensile strength

- Elongation

- Dimensions

- Substrate compatibility

PTFE tape is either a low density material or a high density one. If it is of low density, its density is about 0.37g/cm3 and if it is of high density, its density is0.70g/cm3 or 1.2g/cm3. Important dimensions to be considered in these tapes are thickness, length, and width. Due to substrate compatibility, these tapes are designed for pipes or tubes made of aluminum, brass, or iron. Other PTFE tapes can stick to chrome, glass, or plastics.

PTFE Temperature

Different formulations of PTFE tapes have different temperature ranges but most of all fall in the optimum range of temperature. The minimum optimum safe temperature of PTFE is -200°C while the highest temperature is +260° C. PTFE taps have high melting points and mostly it starts decomposing at temperature above +260°C. It is not applicable for all the PTFE’s tape types and before using any type of tape it is necessary to check its temperature ranges got better performance.

Properties of PTFE Tape

- PTFE tape is hydrophobic in nature that makes it water repellent, and is ideal to use for plumbing and ductwork applications.

- It has very low friction. Therefore, it is used to tighten the piping seals and uncouple them in the future.

- PTFE has lubrication properties that are used to lubricate the sealing joints of pipes. Adding a layer of it to joint threads helps in tighter seals and the lubrication provides low friction to unscrew them in the future.

- PTFE tapes are chemically inert, which means that they cannot react with other elements. Hence these are the best suited materials for environments where solvents, acids, or gases are present.

- These tapes show high arc resistance and work really well in high temperatures. They can be used best in high temperature wire harnesses, coils, and capacitors.

- PTFE tapes have a strong pressure resistance which makes them well suited for high pressure applications such as fuel injection systems.

- PTFE tape has a non-stick backing which means it can be applied and removed easily without leaving any stickiness around the duct joints and pipe threads.

- It is pliable, bendy, and a non hardening material ideal for winding around the pipe threads, compression joints and other fittings.

- PTFE tapes are non corrosive and prevent corrosion of threads.

- PTFE tapes are non flammable.

- Its density is 0.38g/l and tensile strength of 3000 PSI max.

These are the properties of almost all the thread seal tapes but the number of important qualities may vary from type to type. Specific types show specific qualities which makes these tapes well suited for particular tasks and environments.

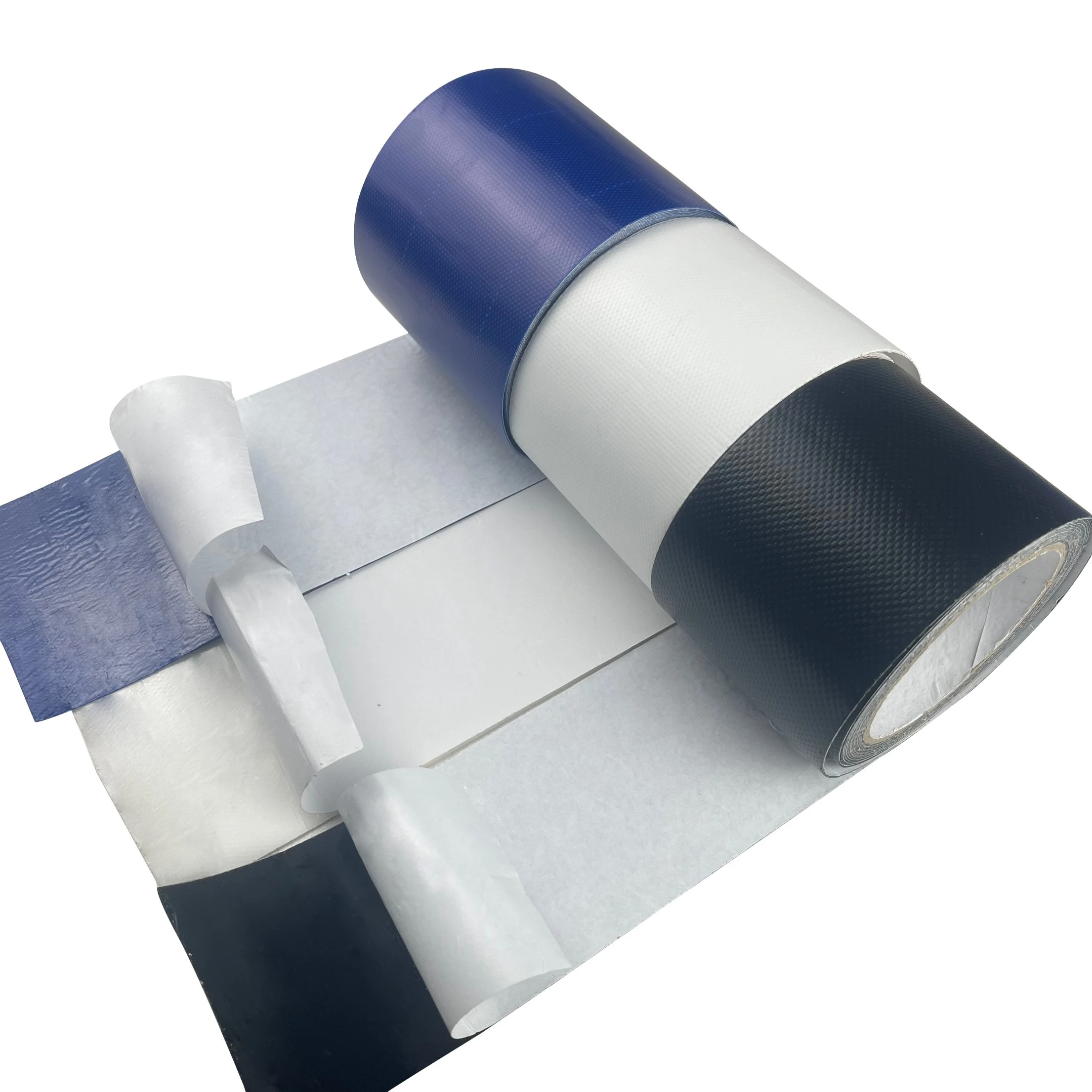

Types of PTFE Tapes

At first, when PTFE tapes were made they only came in one color; that was white. After their huge demand in the piping industry, the manufacturers started making them in other colors also. There are six types of PTFE tapes that depend on the color of the tape, function, and density. These characteristics are different for each type of tape and we will discuss them here one by one.

White Colored PTFE

White colored PTFE tape is a single density tape that is used only on NPT thread of 3/8 inches, but it can also be used in low pressured residential waters such as garden hose, taps, cooking gas connections, etc.

Yellow Tape

Yellow tape has a double density and can be used for natural gas fitting or propane/ butane fittings. It is a gas type because it can be screwed and unscrewed anytime without losing its seal.

Red PTFE

Red PTFE tape is a triple density one. The tape packaging is red, but the color of the tape itself is pale pink. It works for all the joints of ½ diameter or greater than this. It is also workable for high pressure residential water pipes with an optimum operating temperature of 190° F and a pressure of 150psi.

Green PTFE Tape

Green PTFE tape is an oil free tape that is used for pipes that are supposed to convey oxygen such as medical oxygen cylinders pipes or oxygen welding lines.

Copper Colored PTFE Tape

Copper colored PTFE tape is used as a thread lubricant not a thread sealant and it also contains granules of copper in it. It is used as a thread lubricant for pipes and bolts where the mechanical application is required and no physical seal is needed.

Silver PTFE Tape

Silver colored PTFE tape contains grains of nickel either grounded or impregnated. Impregnated grains of nickel are better than powdered. It is used both as a sealant or lubricant. It is designed to prevent seizing when it is used on stainless steel, brass, and aluminum threaded connections and galling while using stainless steel. PTFE is approved only as a thread sealant when it is applied correctly.

Chapter 2: Manufacturing PTFE Tape

PTFE is a fluoropolymer that is made of tetrafluoroethylene molecules. This PTFE has some unique qualities that make it highly demanded in many industries for many products. In this chapter, we will discuss the process of how PTFE is made on a large scale. It is hydrophobic; meaning it cannot be wet by water or any other such substance due to high electronegativity of fluorine, highly non reactive to chemicals, inflammable and extremely low friction rates confirmed in solids. These qualities made it highly eligible for use in many industries, either in kitchens or elsewhere. The annual production of PTFE is about 200000 tons worldwide with daily increasing demand.

PTFE Tape Manufacturing Process

Synthesis of Tetrafluoroethylene

The first step for the synthesis of PTFE is manufacturing TFE polymer. A chemical chamber is heated at a very high temperature to produce cooled and distilled gas that helps remove any impurities present in the chamber. The three main ingredients of this process are hydrofluoric, fluorspar, and chloroform. These are heated in the reaction chamber. After mixing all the ingredients it is turned into a liquid form and then moved to the next stage for further processing.

Suspension Polymerization

The liquid TFE is sent to the reaction chamber for further polymerization. The chamber is filled with purified and clean water then TFE is introduced into this chamber along with the reaction initiator iron. The initiator starts turning TFE into a polymer named polytetrafluoroethylene or PTFE. The cold water present in this chamber will circulate and turn this PTFE into solid grains that will appear on the surface of the water. These solid grains will then be sent into the mill with rotating blades, where these solid grains will be changed into powdered form. This powdered form of PTFE is very difficult to mold. If it is not handled properly it will create air pockets and large lumps in it.

Agglomeration Process

The powdered PTFE is turned into large granules with the help of a process known as agglomeration. In this process, the powder is blended in a solvent such as acetone. It is then dumped into a large rotating drum in which the grains are stuck together to form small pellets. These small pellets are then sent to the oven and are dried there.

After drying in the oven, these pellets can be molded into any part using many different techniques. It is generally from precast to billets. The PTFE billets are placed in stainless steel molds at a very high temperature and then hydraulic press is applied on it. It is heated in the oven for several hours. The product formed with this technique is gel like and then cooled in steel molds. The finished product is then packed and transported to the dealer where they can cut it into smaller pieces for further processing to make their desired products.

Fillers and Additives for PTFE Composites

Sometimes fillers are added into PTFE composites to achieve better chemical and physical properties of this tape. For the improvement of creep properties and general wear of this tape, glass fiber is added between 5-40% in PTFE tape. Bronze is also added to increase its electrical and thermal conductivity which also increases the continuous service temperature. Carbon is also an additive that will increase its hardness and wear resistance. However, these additives are added to the O ring or seals that are friction resistant and stable in corrosive environments such as in automobiles applications.

How to Apply PTFE Tape

Applying PTFE tape is a quite simple process but applying it correctly and using the correct type of tape is very important for better and durable results. The steps to follow for its application are as follows:

- The first step in cleaning the threads of the pipe where tape application is required. Because in old pipes or ducts there might be a lot of dirt, grease, or stickiness present already that will negate the effectiveness of the new application. And also if we are using a new pipe there is a chance of dirt and factory oils or any other particles attached to the threads, so it is better to use an effective cleaner and clean the area properly.

- After the cleaning process, it is necessary to dry out the area properly. This can be done by using some paper towels or letting it air dry. Let it dry for a good amount of time so no moisture is left on the pipe’s threads. If there remains any moisture the tape will not stick together properly.

- Once the fittings are completely dry, start wrapping around the sealant tape. Start from open end one thread down to prevent any material entering the duct. Use the descending direction of the thread for wrapping and back to the top. This is the best way to prevent any type of tape bunching or any disentanglement of the thread.

- The wrapping of the tape should overlap each end with half of its width to ensure its full coverage all over the pipe’s thread. If there is some material deformation present between the threads it will give an extra seal, but it is better to avoid using too much of it as it will cause problems. It is best to wrap the tape tightly to create tension between the threads to make them feel like ridges.

- Continue to wrap the full thread and leave no end. After a complete wrap, cut out the end part and join it with the other part of the tap to ensure proper sealing.

- Use the right type of tape for its specific work. You cannot use oxygen lines tape for water pipelines and vice versa.

PTFE Material Grades

There are some grades of PTFE material with specific properties. These are:

PTFE ISO –TECH

PTFE-ISO TECH is commonly known as Teflon. Due to its very high chemical and thermal resistance along with extremely low friction, it is widely used in the pharmaceutical, chemical, and food industries.

PPS GF40 PTFE SG401E65

It is a low friction compound with about 40% fiberglass that is strengthened with PPS and PTFE. It is designed to work in low friction and surface tension areas because of its low coefficient of friction.

PEEK PTFESG201RN

It is an alloy of PEEK and PTFE designed to work in low surface friction and chemical resistance.

PEEK CF30 G PTFE SGC301 E4

This alloy is 30% carbon that is reinforced with PTFE and graphite PEEK to work exemplary with low friction, better wear, and chemical resistance.

Chapter 3: Applications of PTFE Tape

PTFE is widely used in many areas of life from industries to our kitchens. As it is a thread sealant, the main use of it is in the piping industry for sealing piping ducts.

PTFE Tape for Leaks

PTFE tapes are widely used for the prevention of leaks in pipes. It is used as a preventive measure when two joints are coupling. Wrapping the threads will prevent leakage. This tape will tighten the joint and help prevent future leaks. This tape is for short term uses for leakage prevention, whereas if there is degradation or incorrect joint fixation, this is not the best choice.

PTFE Tape for Gas

PTFE tape is also used for the prevention of gas leakage. But it is useful only if we use the right product for the problem. The tape used for water sealing is quite thin and porous, whereas the gas sealants are thicker and harder and will provide the best solution for gas leakage.

PTFE Tape for Petrol or Oil

PTFE tape is also used for oil and petrol pipe sealing. This tape can cope well under high pressure and high temperature which makes it work well in the automobile industry. It is used to seal the automobile’s pipes of fuel and works well in such oily conditions.

PTFE Flat Sealing Tape

PTFE sealing tape is made from 100% pure PTFE material and it is self-adhesive with excellent creep and chemical resistance properties. It is widely used for sealing purposes in extraction systems, chemical and paint industry, pump fittings, ceramics, ventilation systems, medical industry, pharmaceutical and biomedical industry, fans, turbines, dryers, and food industry.

PTFE Tape in Restorative Dentistry

PTFE tape is used in restorative dentistry; it is used as a barrier against soft tissues and bone formation. PTFE tape is an important thing in cementing and restoration in dental procedures. Metal and plastic stencils are widely used in separating teeth. Clear interdental strips made of PTFE are the best choice because dentists can see and perform their work properly. Stretched PTFE tape is used as an interdental separator and helps in easy dental work. PTFE tape does not interfere with the molding and shaping of teeth but helps correct the positioning and seating of the teeth. PTFE tape is used as a barrier for the peri-implants teeth and protects them during the cementation process. PTFE tape is a non-filamentous one and can be removed easily without any wear or tear. In dentistry, PTFE tape is the best choice to use instead of cotton pallets because it can be removed easily without any bacterial accumulation.

High Temperature PTFE Pressure Sensitive Tape Release Tape

High temperature PTFE pressure sensitive tape is coated with silicone adhesives. This provides a slippery and anti friction surface. The silicone coating helps in complete residual removal. This PTFE tape is used in demolding of various composites such as wind turbine blades, aircraft parts, automobiles, carbon fiber materials, and many more.

PTFE Wear Resistant Tape for Pressure Feet of Sewing Machine

Non-stick PTFE film is non-slip and the adhesive on the single side of the film can be removed without any residual. High chemical resistance and inertness of gases. Good wear resistance and superior flame resistance are the properties of this PTFE tape. It is used in wrapping high temperature and high voltage cables. It provides exceptional mold release in composite bonding. They are also used for wrapping web rollers, noise reduction of parts that rub together and increasing the wear life of parts.

PTFE Tape With Acrylic Adhesives

PTFE tape with single sided adhesive is widely used electric motors, deep well motors, high voltage cables, mining cables, high temperature cable joints, outer insulators of cables and wires, sealing, and wrapping of high voltage wires.

High Strength and Adhesive White PTFE Film Tape

High strength and adhesive white PTFE tape is used as a building membrane with strong one sided silicone adhesives. It has a high temperature resistance of 260°C and dielectric insulation properties. It is used in wrapping and insulation of high temperature cables and wires. It also reduces noise production from rubbing surfaces and many more.

New Upgraded Gray PTFE Film Silicone Adhesive Tape

This upgraded gray PTFE silicone tape is a stronger, higher strength, and heat resistant tape. It is used to wrap the rubbing surfaces of the parts, provides permanent release, and gives superior surface finishes that save time and improve quality. It is also used to protect the rubber tools and helps to extend the tool life. It also reduces cost.

PTFE Film Tape with Silicone Adhesive White

This tape is white in color with silicone adhesive on one side of the tape, which is easy to remove. This tape makes the ink and adhesives spread easily on rollers, plates, and belts.

Specially Oriented High Strength PTFE Tape

PTFE film tape is a single surfaced sheet with high tensile strength and low coefficient of friction and a high pressured silicon adhesive attached to it. This silicone adhesive gives it a smooth and non sticky surface. This tape is used to easily release adhesives on rollers, plates and belts. This machine is specially designed for lamination machines. It is used for wrapping polyethylene laminators specifically for thin laminators where application of tape is easier. It is also used on elongated belts of polyethylene laminators. This tape is also used wrapping web rollers and to reduce the friction of rubbing parts.

PTFE Adhesive Tapes

The base is fiberglass which is coated with PTFE emulsion to form PTFE coated fiberglass cloth. This fiberglass cloth is then coated with silicon adhesive to form PTFE adhesive tape. This tape is a new product in the market with good non-stick properties and excellent chemical and heat resistance. It is also weather resistant and anti-aging between low temperatures of -196°C and a high temperature of 300° C. It is chemically resistant and is very easy to clean any stain. Resistant to all pharmaceutical items and high insulation to UV and anti-static. It is easy to use and has a long life. These tapes are used as an antiadhesive and friction reducers. It is also used as anti-adhesive for dying drums and laminating machines. These tapes are used in high speed sealing and cutting of food and medicine machines for packaging.

Conclusion

- Polytetrafluoroethylene or PTFE is a thread sealant and lubricant.

- It is used in the piping industry on a large scale to prevent leakage of ducts and pipes.

- PTFE tape is of many types specified by its area of application.

- Water PTFE tape is used for residential water pipes, yellow for gas pipelines, and green for oxygen pipes.

- PTFE tape has exceptional chemical and physical properties. It is chemically inert and has excellent resistance to temperature, friction, corrosion, and pressure.

- It is used as a thread sealant and lubricant. It will lubricate the pipes as well as seal them also.

- PTFE is made by a long process of conversion of TFE polymer into PTFE grains.

- Fillers such as bronze and carbon are added into PTFE to increase their strength and resistance properties.

- PTFE tapes are widely used to prevent water, oil, and gas leaks in industries and in homes.

- It is also used to provide anti-friction and anti-adhesive properties to dying drums and laminating machines.

- Certain up gradation of these PTFE tapes, such as adhesives, makes them the best choice in many applications because it does not leave any stain or stickiness behind.